GOS Projects

Simpert Technolgy provides Green Oil Solutions™ (GOS) to save fuel and reduce emissions for the users who consume significant amount of fuel oil for energy production in their daily operation. Several commercially operating GOS projects as illustrated have demonstrated the benefits in fuel savings and emission reduction resulting from the application of Enzergy™, AVS and/or Energy Recovery System.

Petroleum Resin Chemical Plant (GOS)

Simpert Technology has applied the Green Oil Solutions™ (GOS) on this Chemical Company who manufactures petroleum resin and refined naphthalene. This chemical plant has four industrial boilers ranging from 2 to 18 t/h steam generation consuming over 500 Kiloliters fuel oil per month. After the H-031 boiler was implemented with Simpert GES products, the boiler excess air reduces from 80% to 25% and the exhausting flue gas temperature decreases from 260oC to 220oC. Furnace flame became brighter and boiler achieves better combustion efficiency and thermal efficiency.

|  |

Enzergy™ F61 Bio Enzyme

Simpert Enzergy™ F61 bio enzyme can improve dynamic viscosity and fluidity of the fuel oil which can disperse and clean the oil sludge deposit in oil bath and in the pipelines to prevent gum and insoluble debris from clogging fuel injectors and fuel filters. Simpert Enzergy™ F61 contains biochemical micro-emulsification component which can convert O/W micelle into W/O micelle. With water-in-oil emulsion, oil atomization will be more effective resulting in less unburned carbon leaving the combustion chamber. Also the combustion of Enzergy™ treated fuel oil will lower the combustion temperature and prevent the furnace from significant slag & soot buildup. The lowering temperature and less excess air will result in less formation of thermal NOX. |  |

Following photos illustrate the oil filter conditions before (left) and after (right) the application of Enzergy™ F61:

Improve Combustion and Thermal Efficiency

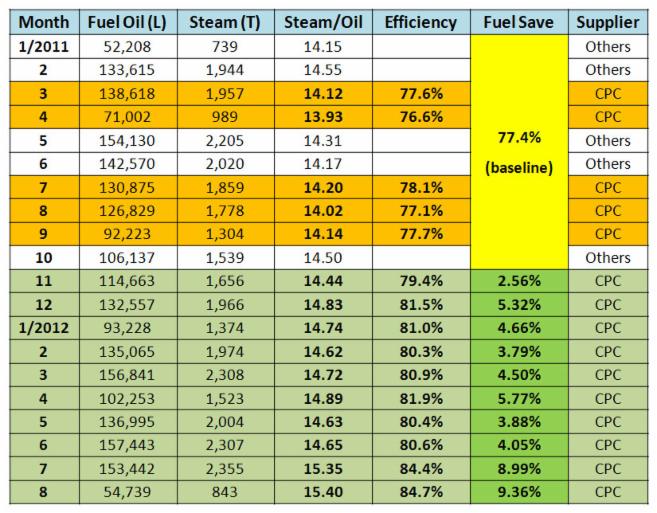

As shown below, the boiler efficiency improves from 77.4% (2011 average) to 84.7% (August 2012) which saves the fuel from 3.8% to 9.4% during the months of GES application:

Following table lists H-031 boiler monthly fuel consumption, steam generation and boiler efficiency calculated by Evaporation Ratio method and ASME PTC 4.1 Direct method:

Economic Benefits from Fuel Saving & Carbon Credits

For a chemical plant consuming 500 kiloliters of fuel oil each month, its yearly fuel cost is about US$ 4,800,000 ($800 per cubic meters). By implementing Simpert GES technology, the average 5% improvement on fuel efficiency will save the plant about US$ 240,000 in fuel consumption annually. In addition to the fuel saving, it will also create about 900 tons of CO2 carbon credits per year which could be traded for US$ 21,600 annually (assuming US$ 24 per ton of carbon tax as stipulated by Australia government starting from July 2012).

![]()